|

|

Frequently Asked Questions about KoalaCoat #25

Frequently Asked Questions

What is KoalaCoat #25?

Koala #25 Balloon Fabric Coating is a product that was developed

over a decade ago in response to the question, “Why can’t a balloon

envelope be recoated?”. KoalaCoat #25 is one of those products that

seems too good to be true, but it is. A balloon that has porosity

can be returned to its original tight, non-porous condition with our

product when applied properly.

How does KoalaCoat #25 work?

KoalaCoat #25 is a recommended 2 stage process. First, using the

Fabric wash, this wipes down the balloon fabric and inserts a

special molecule into the yarn making a normally non-absorbent

material extremely receptive to our coating. Only a light amount is

used. Then the KoalaCoat #25 is applied, usually in 2 medium coats.

It seals the thread completely. Then, the coating bridges the gaps

in the weave, filling all of the little square holes, each of which

are pinhole leaks in the balloon envelope. If applied properly and

thoroughly, the fabric will become 100% non-porous.

How long can KoalaCoat #25 be expected to last?

The life of the fabric. When using the Fabric Wash, the coating grip

is enhanced because the coating gets drawn into the twist of the

yarn making it very difficult to release. Factory coatings typically

have very little in the way of bond with the fabric. The coatings

will just lay on or surround the thread but are not truly

impregnated into it. Therefore, the coatings will crack, chip and

shear off over time.

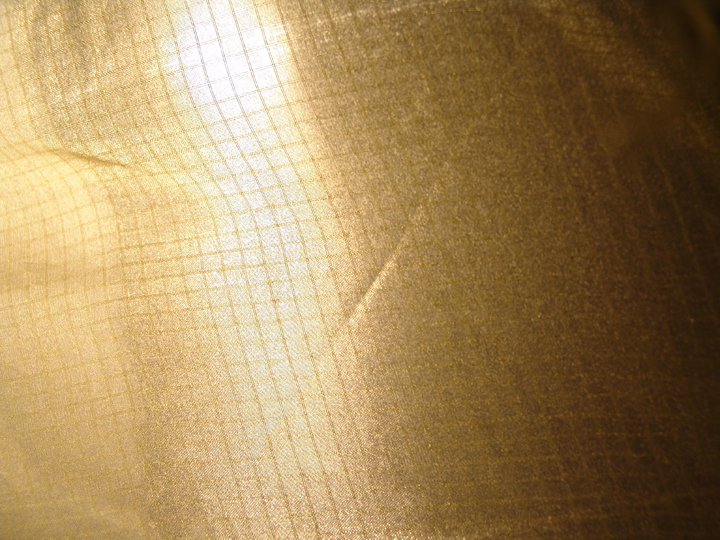

What does KoalaCoat #25 look like?

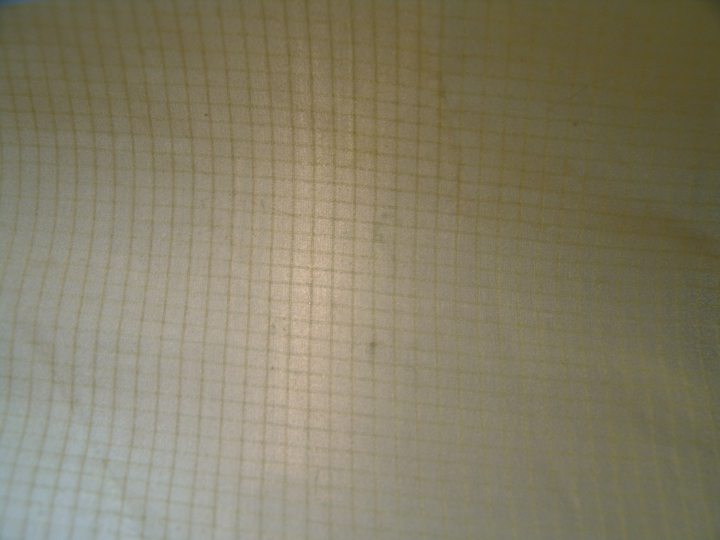

KoalaCoat #25 has an appearance visually to that of regularly coated

fabric. Note the pictures below. The first photo is porous fabric.

Notice how much light passes through the weave? The 2nd

picture is the fabric after it has been coated. The light is

dispersed across the fabric. That is because all the

little holes have been closed up. New balloon fabric looks and acts the same

way.

This picture has a halogen light behind it. The light passing

through the fabric is showing all of the leaks from porosity. This

fabric is 100% porous.

This picture is the same halogen bulb shining on coated fabric. No

pinholes of light means no porosity.

What does KoalaCoat #25 feel like after it is applied to the fabric?

After KoalaCoat #25 cures, it has a slightly crispy, very springy

feeling. In fact, it is difficult to pack away the envelope after it

is freshly coated because it wants to spring out. The envelope will

also hold air like a new balloon. After about 20 or so flights, that

feeling will start to diminish. The balloon will start to get a very

nice soft, well worn, favorite old shirt feel. The coating is now

broken in. That doesn’t mean that the coating is breaking down. The

balloon will continue to be non-porous for at least 100 hours. In

fact, we have never seen KoalaCoat #25 treated fabric that ever

became porous again, and there are balloons that have had the

coating for well over 200 hours.

Does KoalaCoat #25 weaken fabric?

No. Certified tests which are published on our website show that

there are no negative effects on either nylon or polyester

materials.

Will KoalaCoat #25 lower the operation temperature of the

balloon?

No, in fact, there is no melting temperature for KoalaCoat #25. In

fact, when testing KoalaCoat #25, our oven temperature regulator

failed and the temperature skyrocketed until the heating element

failed. Our best estimate is the temperature in the oven exceeded

700 degrees F. The fabric samples charred but the coating held the

burned material together and the now very fragile fabric was still

completely non-porous.

Will KoalaCoat #25 affect the airworthiness of the aircraft?

No.

Does water affect KoalaCoat #25?

Yes. Moisture will accelerate the cure. On humid summer days, the

coating cures much faster. After it cures, the coating repels water

(hydrophobic). It will also not support life such as mold or mildew.

Is KoalaCoat #25 flammable?

You betcha! Do not expose the uncured materials to sparks or flame,

PERIOD! After it cures, the flammability drops dramatically and is

about as flammable as the fabric itself.

Why does the Limitations Sheet state that you can only coat the top

2/3’s of the balloon?

The bottom third of the balloon really does very little for lift.

Furthermore, the lower part of the balloon is exposed to flame and

for the first few hours of cure, it would be a risk to fly if it was

freshly recoated to the mouth.

How much fuel can I expect to save if I use KoalaCoat #25?

It all depends on how much the balloon is using now. Whatever amount

the balloon consumed new is how it should perform again. But, most

importantly, is not how much fuel you will save in order to save

money, rather, the length of time in air time you will be afforded.

There is nothing worse than flying and constantly monitoring the

fuel gauges because your balloon is sucking down propane at a rapid

rate. Fuel management is one of the most important parts of flying.

When you run out of fuel, you will stop flying, whether you want to

or not.

Can my repair station do the work for me?

No. The approval requires that KoalaCoat #25 be applied by the

Owner/Operator of the aircraft. The concept is that it is less

expensive to do the work yourself and the owner/operator is

responsible for his work.

What is the average cost to coat a balloon with KoalaCoat #25?

For a 77-105 envelope, a good guess would be around $1500-$1800.

Interested in finding out more? Click here to go to the Koala #25

Webpage.

|